Production of the Amsted-Rail LLC

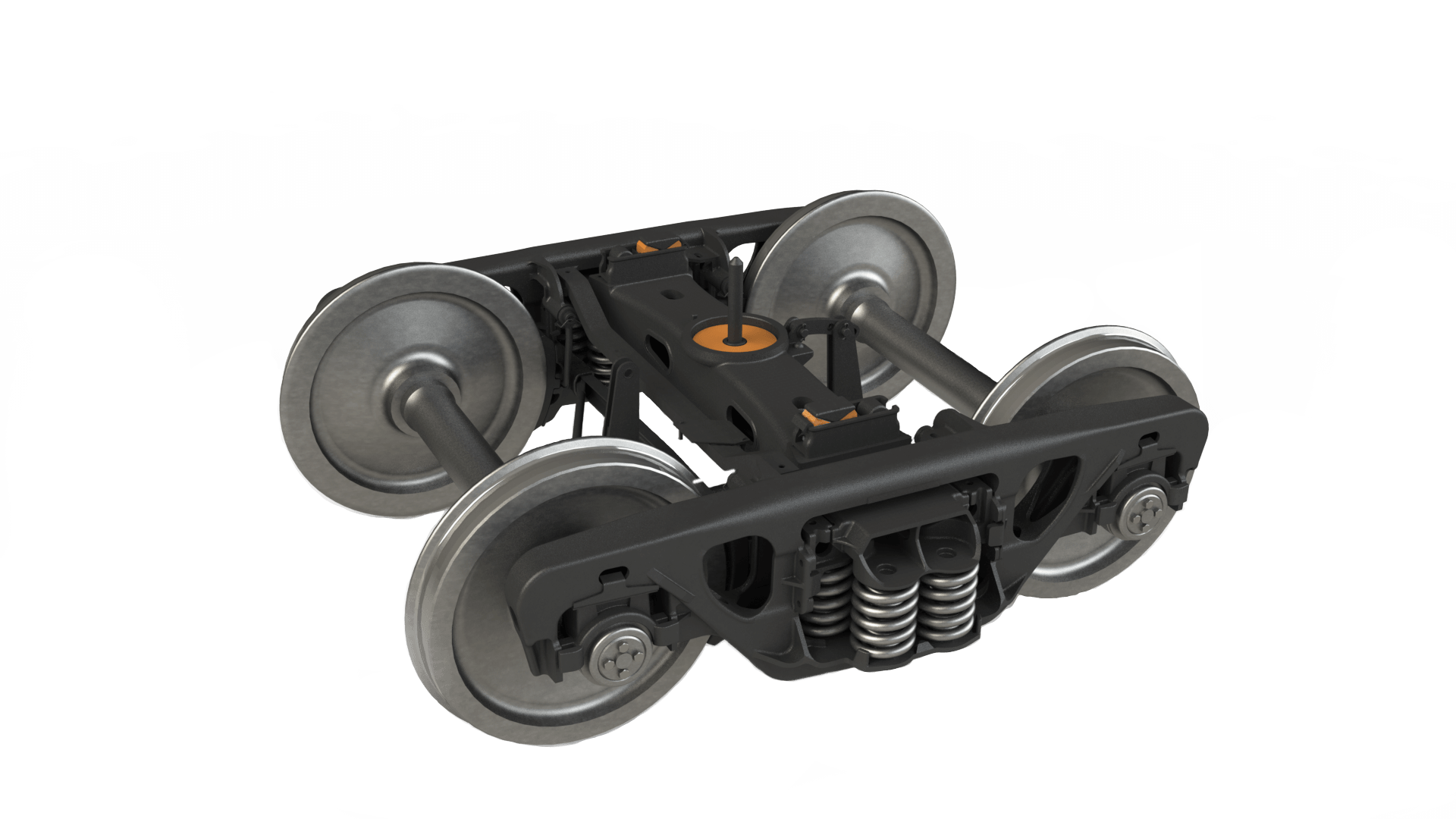

Details applied in the complex modernization under the C03.04 project and in innovative bogies

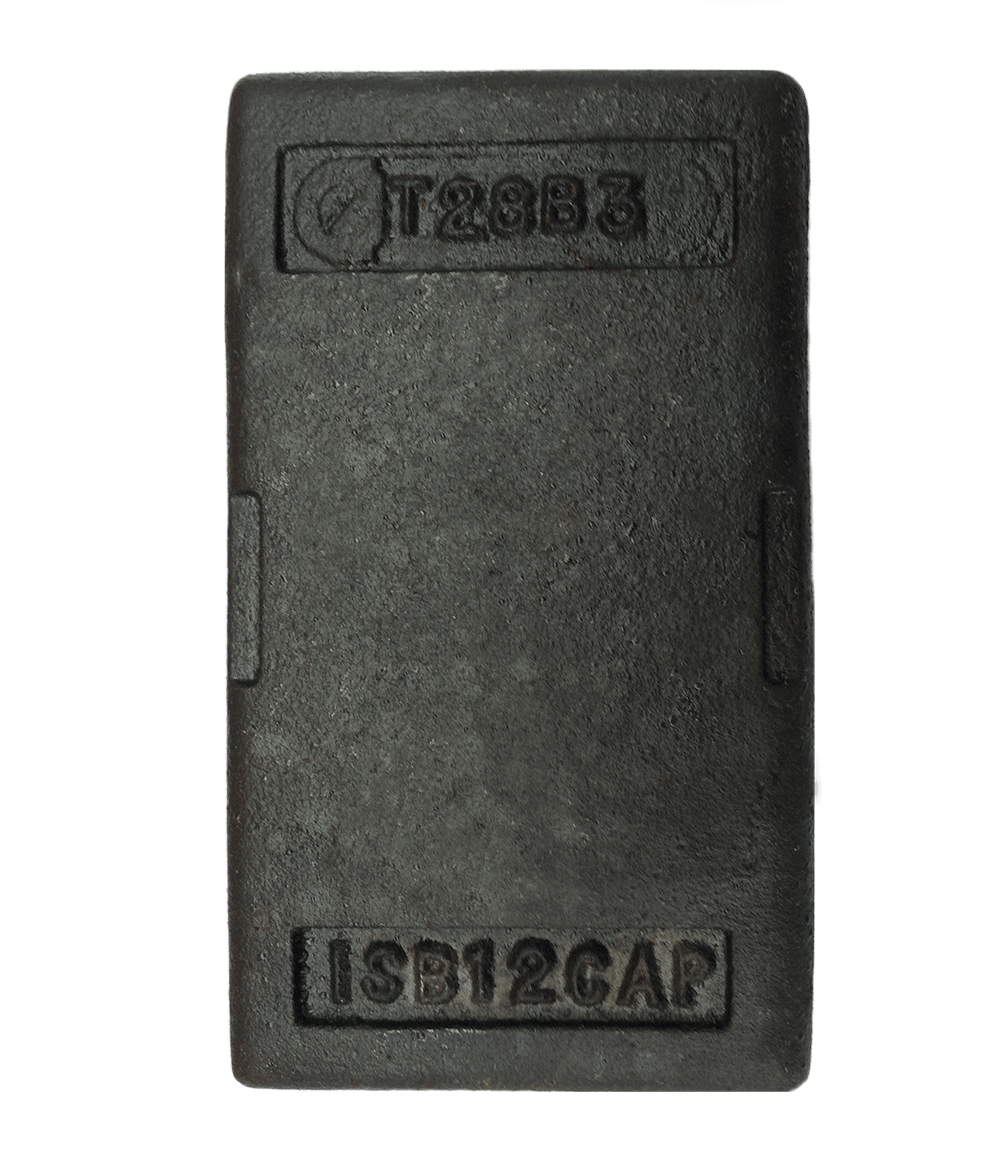

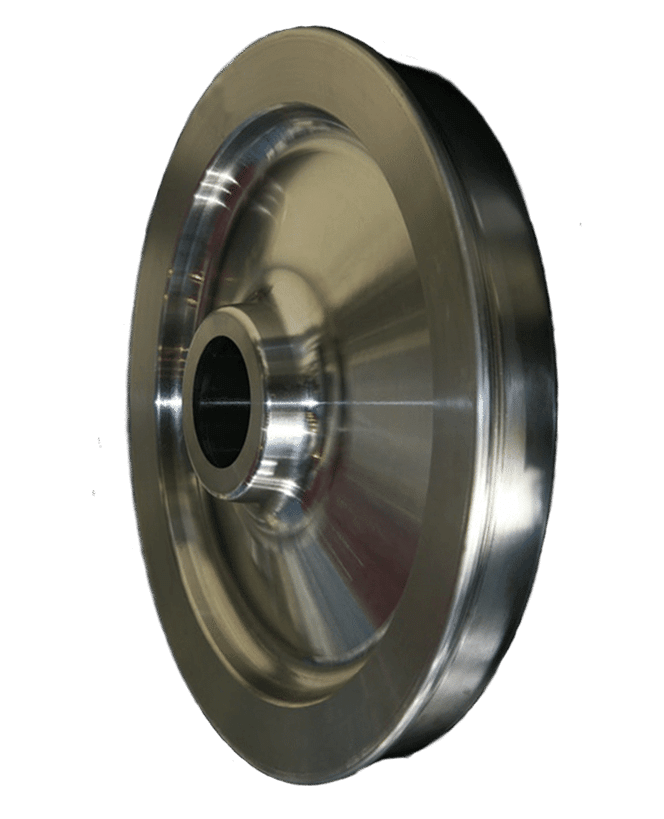

Resilient roller side bearing ICB-12

The side bearing of this model combines a high reliability, simple design and easy maintenance. The travel of the side bearing is 6 mm. It is mostly installed on railcars with a truck-center spacing up to 10 – 12 m and car body with a weight over 11.5 tonne.

It is a compact side bearing with a resilient elastomeric element in the form of a hollow cylinder. This side bearing has an extended travel (preload) – app. 16 mm due to which it may successfully applied on railcars with a truck-center spacing over 14 m. This model may be equipped with resilient blocks with a 4500, 5400 or 6000 lb preload which allows using the side bearing on railcars with the car body weighted over 9.6 tonne.

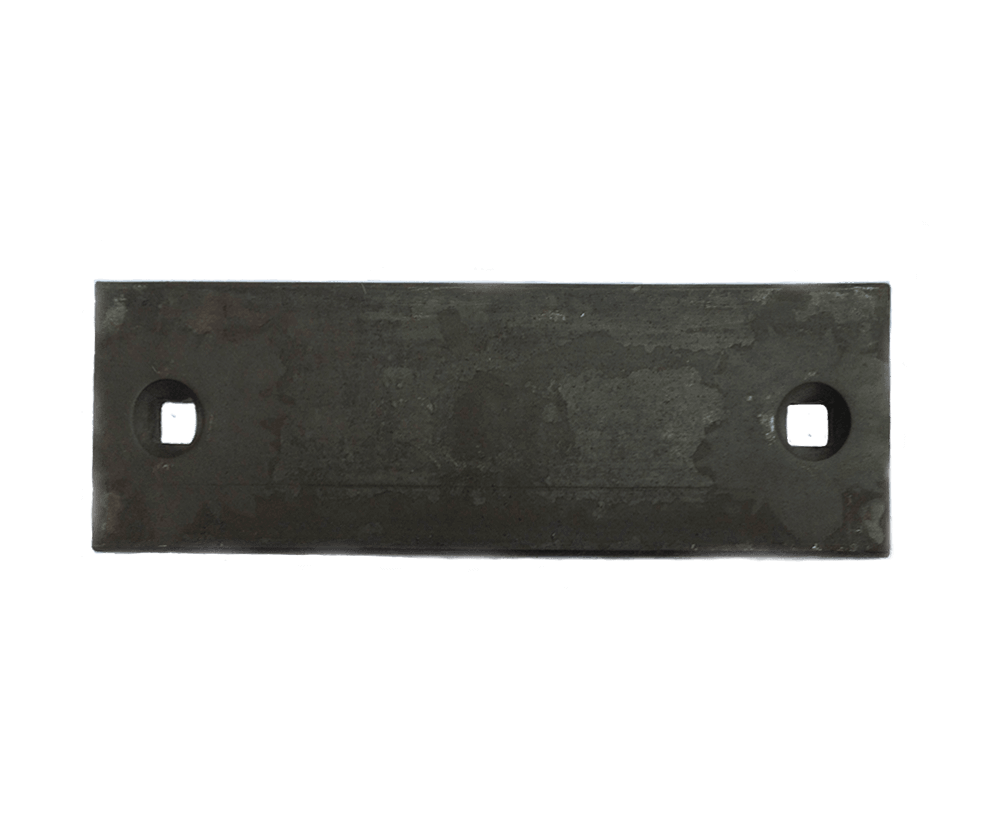

The wedge of this model is made of austempered cast iron and has a polyurethane pad on the diagonal surface in addition. The application of such friction shoes in combination with steel friction plates of high wear resistance allows to multiply increase the life of the friction shock absorbing system

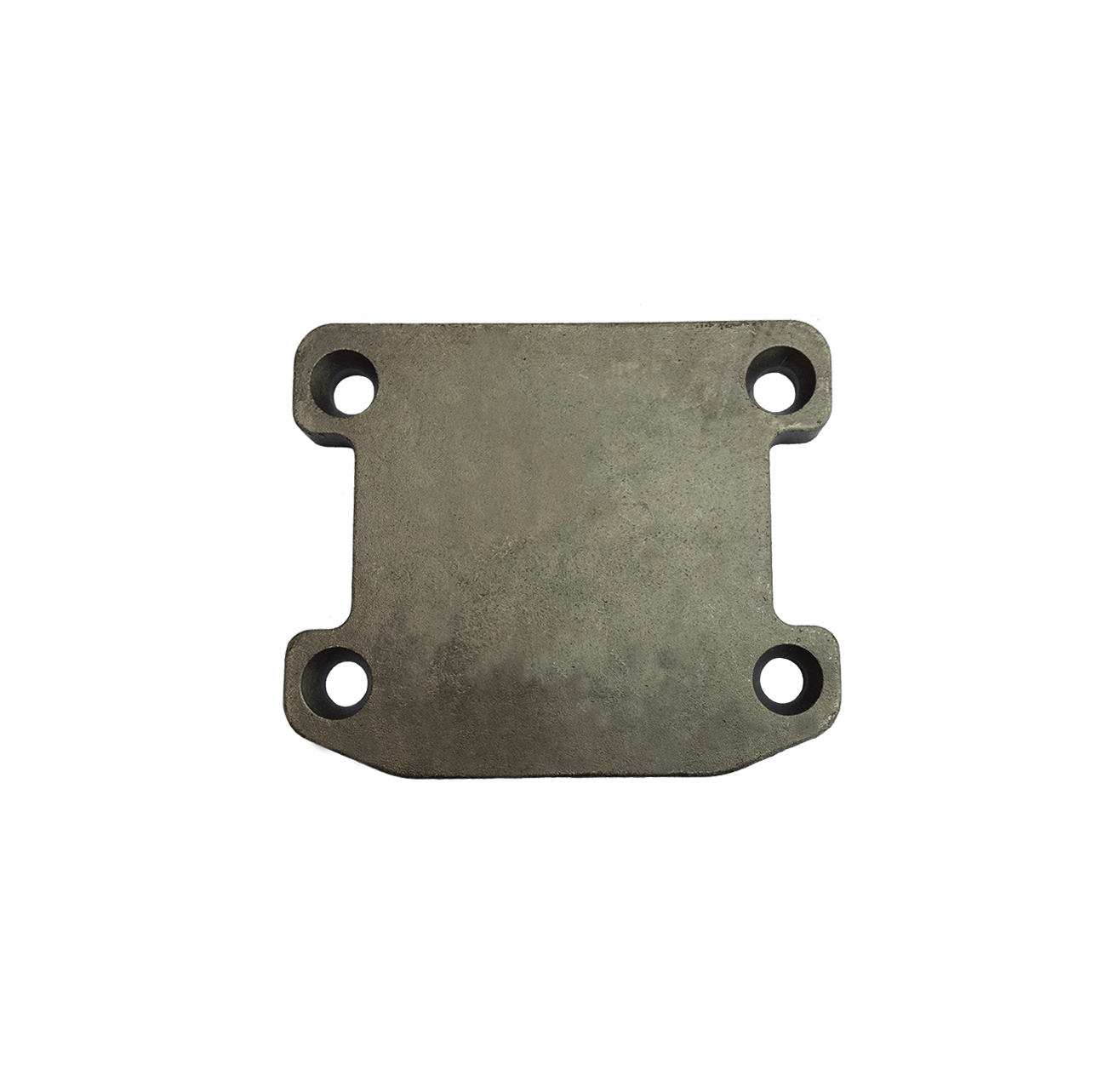

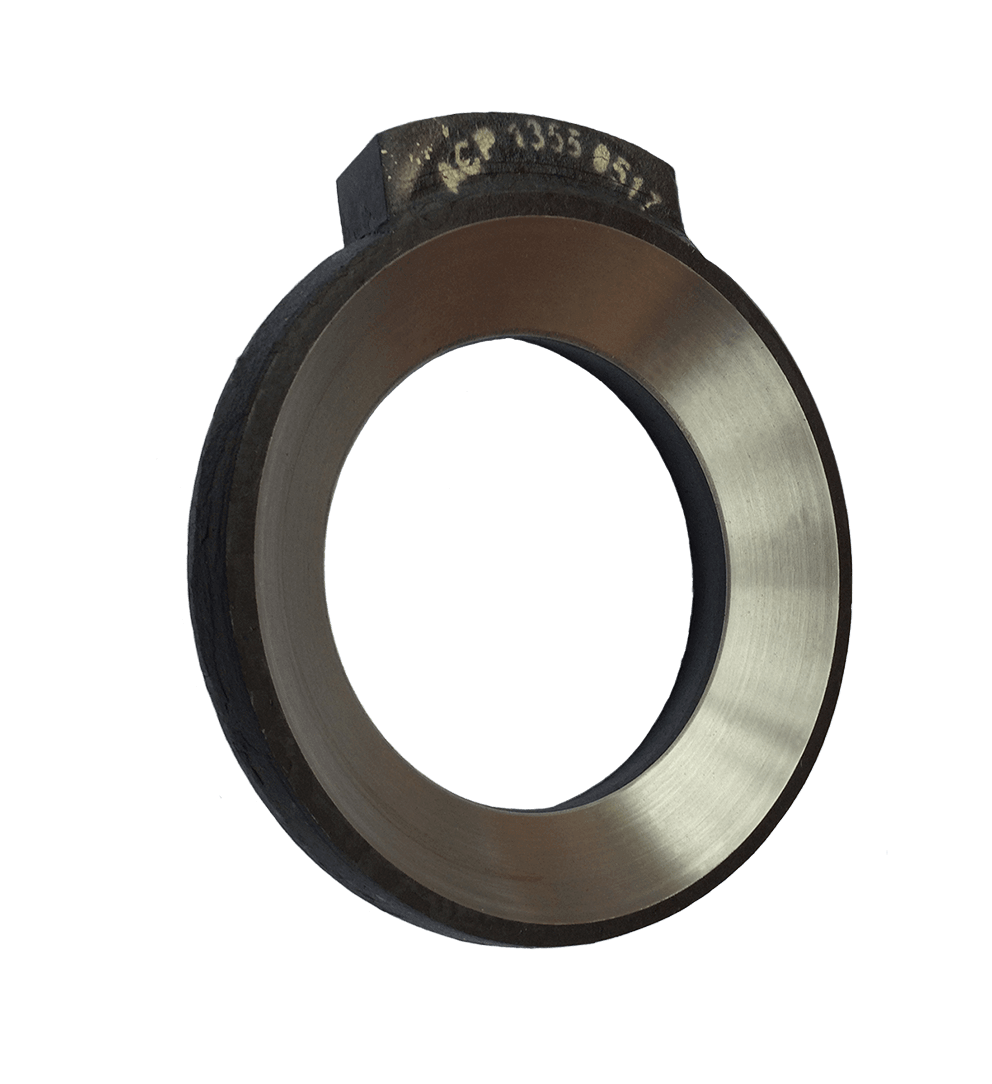

In order to improve the function of the center plate unit, center bowls are equipped with polymer liners made of a wear-resistant material with a low coefficient of friction and due to this they do not require any lubrication. The application of the polymer liner in combination with constant contact side bearings, friction shoes with polyurethane pads and friction plates with high wear-resistant features allows to significantly reduce wear of the center plate unit.

Screws: KV1-M20; KV1-M22. Screws U.S.A.: 7/8 inch with breakaway heads. Nuts: KV1-M20; KV1-M22. Nuts U.S.A.: 7/8 inch, 3/4 inch. Wash 22.

Is is installed on the wagon body it is in contact with the side bearing cap

The wear-resistant wheel profile is developed in the Institute of Technical Mechanics of the National Academy of Sciences of Ukraine specifically for its application in the bogies subjected to complex modernization. Due to the application of this profile, wheel flange wear is reduced more than two times.

Details of the shpinton unit of the passenger car

Shpinton friction elements of the passenger car bogie operating under dry friction conditions and side bearing inserts made of a wear-resistant material using our technology make it possible to run over 1,200,000 km without any repair or replacement.

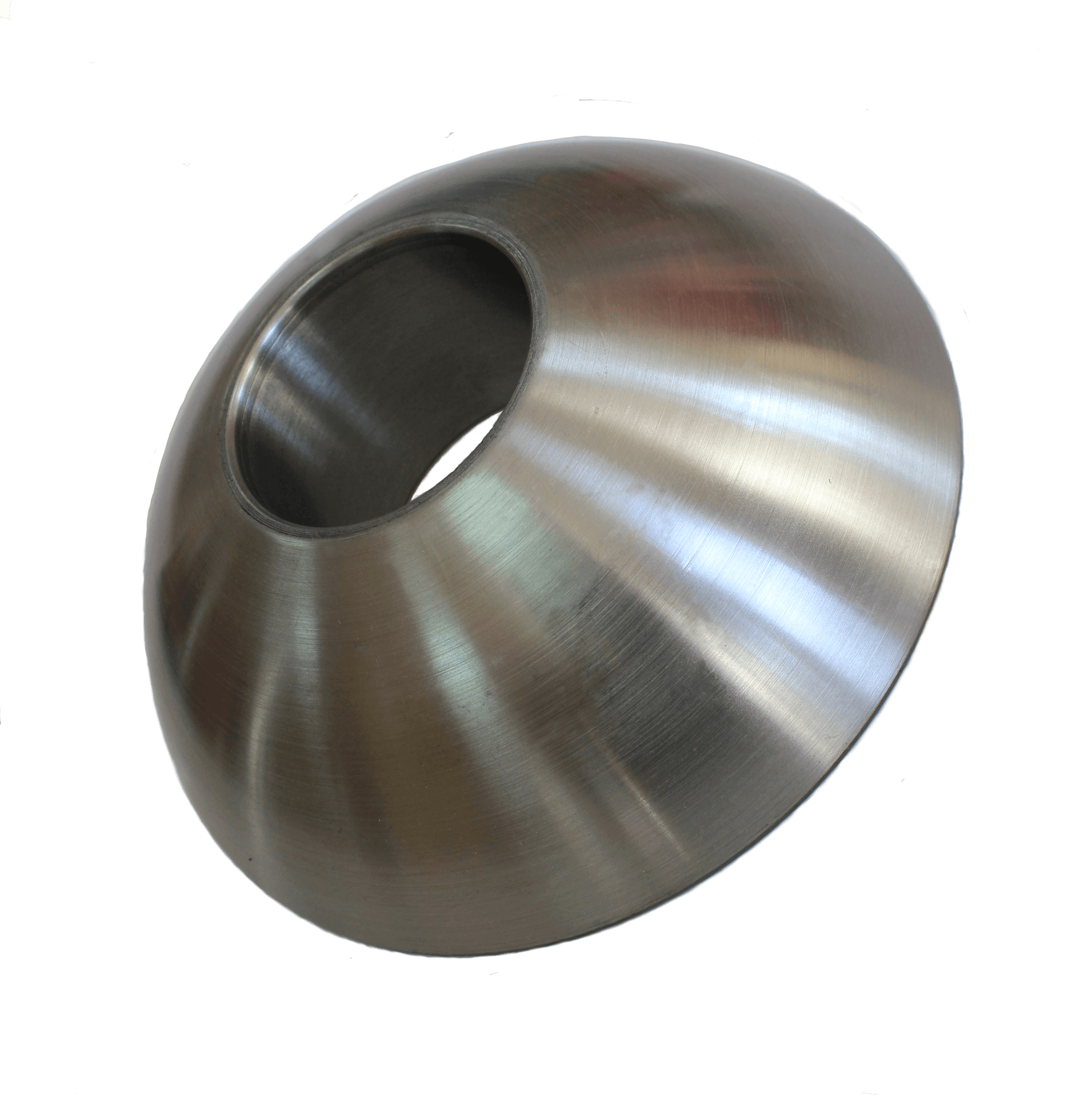

Details of the ball support for the locomotive of the CME-3 series

The parts of the ball joint made of a wear – resistant material using our technology allow to stop using lubricants as spheroidal graphite containing in parts acts as natural lubrication and significantly (up to 10 times) increases the service life of the unit in comparison with conventional parts.

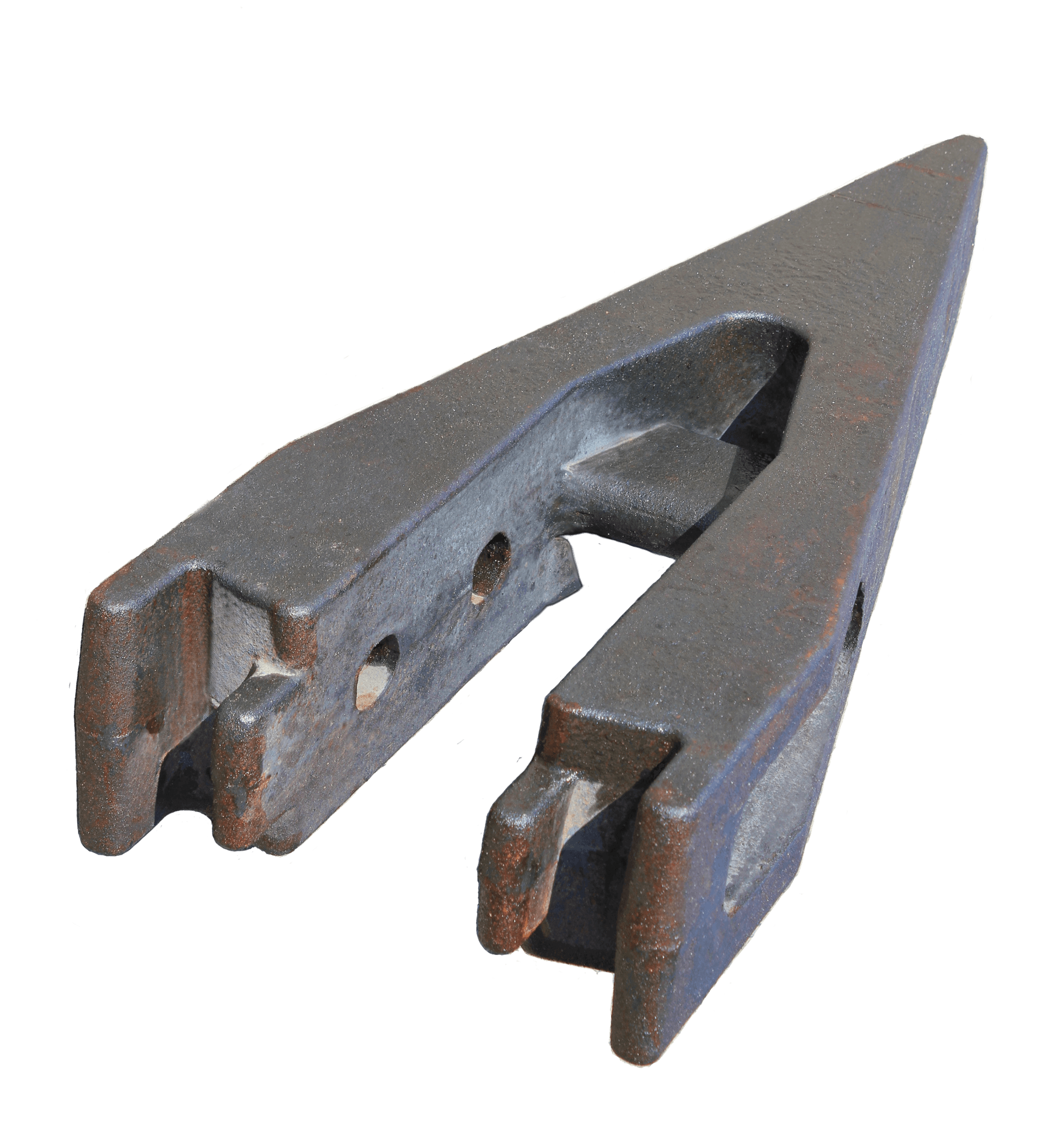

Earthmoving machine

Excavator tooth of special high-strength cast iron. The tooth is hardened using the austempering process, and is of higher wear resistance (with a length of 880 mm).